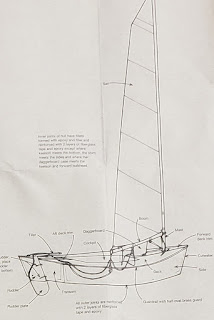

Clancy was billed by its chief promoter, Bob Pickett, as a "10-foot sailboat of exquisite form and commanding performance." Weight is quoted at a car-toppable 85 lbs, and when coupled with it's 55 sq. ft sail, the boat is capable of planing "under the right conditions."

In Pickett's words, the boat was intended to be "the most sailboat you can squeeze out of a 10-sheet of plywood." This is in refence to the fact that the boat was designed around the then-accessible (through Pickett's Flounder Bay Boat Lumber), but now nearly extinct 4x10 sheet of plywood. Three sheets of 1/4-in marine grade 10-footers comprise the hull bottom, sides, deck and bulkheads. A (equally hard to find) half sheet of 1/2-in ply is also needed for the transom, kingplanks and daggerboard trunk, while 3/4-in ply is specified for the daggerboard. Various pieces of solid timber are required for the keel, keelson and other miscellaneous structure. Aluminum tubes are specified for the spars.

Construction is cited as being stitch and glue, though this claim is not wholly accurate. There is some similarities to a stitch and glue boat in the final product, in that it is a monocoque hull, made from plywood, held together with epoxy fillets and fiberglass. There is, however, little in the method of construction that bares a resemblance to stitch and glue. In stitch and glue, hull panels are cut to very precise shapes -- the shape of the panels wholly determining the hull's final form -- and then stitched together as the seams with wire before being permanently bonded with epoxy. On Clancy, the hull is built upside-down on a jig. The bulkheads, keelson, and stem are secured to the jig, and then the slightly oversized hull panels are attached and trimmed to size. The method is a hybrid, with DNA from stitch and glue and plywood on frame, with just a little of Tolman skiff thrown in. It is a method that is rewarding, fast, and easy for a first timer, though perhaps not any more so than stitch and glue.

In his introduction to his New Yankee Workshop episode on the Clancy, Norm Abrams calls the Clancy of "refined model," yet a closer look at her lines do show some rough spots. The boat is not unattractive over all, but plywood does not appear to have been the designer's most familiar medium. The hull bottom is not developed, i.e. of a conical section so that the plywood can bend to it without being "tortured." The is evident from the fact that it is flat from the forward bulkhead to the midpoint of the cockpit, with some curvature or deadrise aft. This, in turn causes the forward hull bottom to want to take an inverted "V" form, which has to be forced flat when the hull sides are installed. There's an aggressive upsweep in the shear line that, if not unfair, seems.to be at least a little of of proportion. Compared to its stitch and glue contemporaries from Pygmy or Devlin, Clancy is clearly a little less refined in design. More unfairly, a look at modern boats such as Chesapeake Light Craft's Peapod shows just how far the art has come with the help of modern CAD/CAM tools and CNC machines.

No comments:

Post a Comment